Hi,

Do you know how to use a DMM and how to read circuit diagrams?

If not, as there are hazardous, even lethal voltages inside the amp, if you don't know how, because you will need to know to find the problem, then I recommend that you contact a reputable, professional electronics repair service and ask for a quote to repair the amp.

Hi @slowboy ,

OK.

Just so that you are aware that there are hazardous and possibly lethal voltages present.

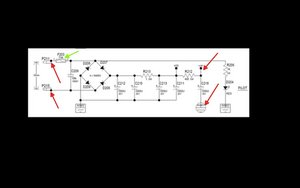

Here is an image showing the input circuit to the power transformer. You can perform a static test on this circuit to prove it is OK, i.e. test it with the power disconnected completely from the amp

It is taken from a Peavey Valve King 100 (212)(which I hope that yours is), circuit diagram Forgive the crude additions made by me.

(click on image to enlarge for better viewing).

Using the Ohmmeter function found in a DMM, place the Ohmmeter test leads across the Line and Neutral connectors in the amp power input socket (as shown by the 2 red arrows) and operate the Power switch on the amp. There should be a reading on the meter, because the meter is 'seeing' the primary winding (red squiggly line) of the power transformer. If there is no reading, first check that the DMM is set correctly for Ohms (s/c the test leads to prove that the DMM works and you read 0 (zero) Ohms), if still no reading across the power input terminals with the Amp Power switch on, then you have to do a point to point test of the circuit. Start with one test lead on the L connection in the socket (leave it there and only move the other lead) then place the other lead on the F204 fuse and see if the meter shows a reading. If it does move the test lead to the next point in the circuit, the Power switch and check there and so on until you find out where there is no longer any meter reading. The problem lies between where the two readings, one good the other bad are. The problem could either be dry solder joints, broken or loose connections or even a loose fuse holder, etc. If you find that there is no reading 'through' the Transformer (P213 & P214) the winding is o/c, OR perhaps the connections to the windings are broken or dry solder joints.

If the power input circuit tests OK then this image is of the valve heater circuit and also the Power On LED. If there is no valve heater power supply then the valves won't work even if the other power supplies to the valves are OK. They won't 'glow'. I'm old enough to have been taught how valves work so as to be able to work on circuits containing them (national telephone network transmission circuits), transistors were the new kids on the block back then. ICs were yet to come

(click on image to enlarge for better viewing).

Initially test directly across P211 & P215. You should get a low reading. This is one of the secondary windings of the power transformer. If you get no reading at all, again check the connections to this winding.

If this winding tests OK then you now have to test with the power on.

Be aware of the dangers! You now have to use the DMM as a Voltmeter.(set to Volts DC initially highest range to safeguard the DMM). If you can, use the DMM with alligator clips on the end of the test leads. That way you can connect the meter leads to the test points before turning on the power so that you are not in anyway touching anything inside the amp with the power on.

Always switch off the power, on the Power switch and also the wall outlet before reaching into the amp.

Place the test leads between the chassis of the amp (ensure a good bright metal connection point) and either the valves heater connection (HTR - or the other side of R212 from which the +14V test point is connected) or +14V test points (which you will have to find on the circuit board). Connect the power to the amp and switch on. You should get a reading around 14V DC on the DMM. if there is no reading there may be a problem with Fuse 203, the diodes D206 - D209, R213, R212 or any connection between them.

Hopefully this is of some help. Be careful and stay focused on what you are doing

Hi Keith,

Thanks for the pictures it really helped.

I think that the problem in on the pad below the fuse that the P1 wire is connected to. I maybe wrong of course.

Here is an image of what I think the fuse connections are from the Line input and the P1 switch.

(click on image to enlarge for better viewing)

Put the fuse back into the holder, with the cap to hold it in. Then place the Ohmmeter test leads across the two pads as shown in the image. If you do not get a reading then there is a problem with either one of the two connections, (basically where the arrowheads are) or the fuse holder itself. I'm leaning towards the "P1"end of the fuse pad connection being the one. Also try "moving"the fuse holder (you said it was loose) to see if the reading comes and goes. Either way hit both of them with a soldering iron to melt the solder to establish a good connection.

If you cannot get a reading between the two fuse connection solder pads with the fuse in AND you have resoldered the connections then the actual fuse holder is faulty and will have to be replaced.

Just playing devil's advocate, have you got the correct sized fuse inserted? Not the rating of the fuse but its' dimensions, so that it will touch the connections inside the holder OK. Have a look inside the holder with a torch and magnifying glass to work out how the fuse ends 'touch the terminals inside the holder. If you cannot get a replacement fuse holder to fit then you may have to "jury rig" an alternative such as an appropriate inline fuse or something similar.

To verify that the fuse connection or the fuse holder itself is the problem, connect the meter between the fuse's P1 "solder pad" and the P1 switch terminal and you should get a reading. If so operate the switch and connect the meter between the fuse's P1 "solder pad" and the Neutral input terminal. If there is a reading this proves the circuit from the fuse "output" through the Power transformer all the way to the power input. Next place the meter between the fuse's Line "solder pad" and the Line input terminal. You should also get a reading. This proves the circuit to the fuse's "input".

Был ли этот ответ полезен?

Проголосовали

Отменить

Счет

4

Отмена

Прокрутите эту тему, чтобы найти подходящее место для этого комментария. Затем нажмите "Прикрепить комментарий к этому сообщению", чтобы переместить его.

2

2  5

5

1,5к

1,5к

1 Комментарий

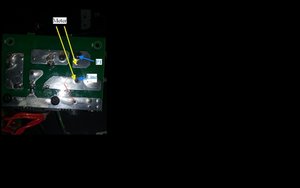

here's picture of circuit board [3] where F204 fuse holder is mounted...red arrow points to where solder seems to be missing...not sure, but maybe point of problem?...

[image|1069152]

из Keith Pike